Outstanding Green Makers

The Flax Project C.I.C.

Vicky runs Flax Project CIC which aims to revive the flax industry in South West and bring linen production to the Tamar Valley and Plymouth, linking the city to the surrounding countryside. Her aim is to create a locally produced linen with a low carbon supply chain from field to fabric. Slow textiles, small farming.

Precious Plastics

Precious Plastic Plymouth and Tavistock is a low-tech, artisan plastic recycling project. Their mission is to provide a tool for local recycling and creative engagement to empower the community to live sustainably. We take waste plastic, shred it and re-mould it, using a small injection moulder.

Bellacouche

Bellacouche, the UK’s first dedicated wool shroud making enterprise. The design is unique, weighing less than a third of the weight of an average coffin. Tried and tested over two decades, the Leafcocoon has become increasingly popular for those seeking an environmentally friendly alternative to a coffin.

Imogen Taylor-Noble

Imogen is a researcher, maker, teacher, and activist with a socially-engaged ceramics practice.

Imogen is currently working on a project to investigate the possibility of making 100% industrial waste stream glazes to use in her practice.

Upcycled Glass Company C.I.C.

UGC is a CIC based in Dartmeet, revolutionising the glass industry. Using cutting-edge technology and tried and tested glassmaking & farming methodologies, they are working on solving the growing ecological problem of what to do with the mountains of end-of-life building & art glass that can’t be commercially recycled.

Woodlab

Woodlab are an elite squad of timber saviours, who wake up in the middle of the night thinking about furniture design, trees and solving problems.

Their mission is to unite artistry and ecology, and to craft a lasting legacy for British woodlands.

Pledged Green Makers

All the makers listed (in their craft categories) below have signed the GMI pledge to actively reduce the environmental impact of their making practice. Find out more about each maker by clicking the link to their bio or website.

-

-

-

Abigail North | Website

Alipwm Pottery | Website

Alisha Norman

Alison Shelton Brown | Website

Alison West Ceramics | Website

Amanda Harvey Art | Website

Bethan Jones Ceramics | Website

Blungers

Bridget Macklin | Website

Caroline Aisher Ceramics | Website

Christina Peters | Website

Community Clay (OSR Projects) | Website

Create (Cornwall) CIC | Website

eARTh Pottery | Website

Edie Evans | https://www.edie-evans.com/Website

Gabrielle Tymkow

Gill Bliss | Website

Hayley Potter | Website

Helen McCormick Ceramics | Website

Imogen Charleston | Website

Imogen Taylor Noble | Website

In The Making | Website

Jana Gilfillan | Website

Jason Marks | Website

Jayne Randall Pottery | Website

Jilly Russell | Website

Jocelyn Doe-Goodman

Kate Williams | Website

Lauren Kershaw

Lorraine Gilroy

Lucia Yonge | Website

Noriko Nagaoka Ceramics | Website

Owen Rees | Website

Poly Pottery Falmouth | Website

Associate Professor Polly Macpherson | Website

RAMP Ceramics | Website

Sara Evans | Website

Sarah Cooper Conway | Website

Sarah Shorthouse | Website

Sarah Sullivan | Website

Seaside Ceramics | Website

Siobhan Joan | Website

Stefania D'amico

Steven Gatrell Sales | Website

Studio Mush | Website

Tania Clarke

Tim Russell | Website

The Clay Yard | Website

Thyme and Space Ceramics | Website

Toni Fairhead

-

-

-

Andrea Dritschel Jewellery | Website

Ania Jewellery | Website

BellEve Seaglass | Website

Bex & Bolt | Website

Charlotte Eatock Beach Clean Jewellery | Website

Claire Lowe Jewellery | Website

Clare Maiden Jewellery | Website

Daisy Dunlop | Website

Dawn Gill | Website

Donna Burns | Website

Emmeline Kwaan | Website

Expanded Skies | Website

Fiona Cock

Freya Mohan

Gareth Treseder | Website

Hannah Brown | Website

Hannah Stickland

Iona Hall | Silversmithing | Website

Isabella Day | Website

Kathleen Ashcroft Jewellery | Website

Kaja Jewellery | Website

Laura Drayson | Website

Lynette Price | Website

Maya Ullman | Website

Oresome Jewellery | Website

Peter Reeves Jewellery | Website

Planet Saz Designs | Website

Rachel Darbourne | Website

Rowena Mynott Silversmith | Website

Sarah Clarkson

Sarah Hemmings-Vourda | Website

Sarah Webster | Website

Shiryun Jewellery | Website

Shore & Silver | Website

Storm & Grace | Website

Tracy Stagg

Trinity England | Website

Trinket and Trove | Website

-

-

-

Allie Cole Art | Website

Animal Glass Designs | Website

Beth Jordan Studio | Website

Bonnie Mustoe-Whitehill | Website

Charlotte Squire | Website

Clair Tompkins | Website

Eleanor Darley | Website

Exe2Sea Handcrafted Products | Website

Frances Staniforth | Website

Helen Edwards Mixed Media Textiles | Website

Jane Gray Sustainable Designs | Website

Lisa McEleny | Website

Little Burrow Designs | Website

Lyn Edwards | Website

Mungo Sweet | Website

Oliver & Purchase | Website

RE Treats Plymouth | Website

Rosemary Lincoln

Sam Isaacs (reworked) | Website

-

-

Bristol Broomworks | Website

Chris Marshall Craftsman | Website

Echoes of Earth | Website

Emmie Clare | Website

Flora’s Soap | Website

Gemma Carter | Website

Green Shoes | Website

Isla May Eko

Kate Crawfurd | Website

Katherine House | Website

Katie Moore Studio | Website

Lizzie Stevens | Website

Maker Mews | Website

Megg Evans | Website

Mel Le Bars

Moorswood | Website

OrganicARTS | Website

Plymouth Scrapstore C.I.C. | Website

Princetown Press | Website

Wild As The Wind | Website

Sarah James | Website

Sonya Ellis | Website

Sophia Tapper | Website

The Hedgewitch Soapery | Website

-

-

Andrea McCarthy | Website

Catherine Cartwright | Website

Community in print | Website

Double Elephant Print Workshop | Website

Flotsam Prints | Website

Gillian Spottiswoode | Website

Isla Middleton Design | Website

Kimberly Rainford Art | Website

Lisa Lucas | Website

makerslane.uk | Website

Merlyn Chesterman RE | Website

Niamh Geraghty-Morris | Website

Pine Feroda | Website

Rebecca Child | Website

Stewart Taylor | Website

Tideline Prints | Website

Victoria Owen | Website

-

-

Abeer Kayani | Website

Adele Thomas | Website

Ali Roscoe

Alisha Gallagher | Website

Anne Bulleid

Bridget Arnold | Website

Caz Green

Charlie Lewin | Website

Chloe Haywood London | Website

Creative South West | Website

Darn Good Studio | Website

Dartmoor Weaver | Website

Emma Sherriff | Website

Emotional Baggage

Esme Cooper Design and Print | Website

Felting Feels | Website

Fliss Cleaver | Website

Fruitbat Textiles | Website

Garker Fields

Gilly Riddington

Glass Shed Studio | Website

Hannah Wisdom | Website

Honest Weaves | Website

Jo Hague | Website

Joy Merron

Judith Archer | Website

Julia Bond | Website

Liz Clay | Website

Mary Toon | Website

Mateja Perosa | Website

Mend Assembly | Website

Seam Haberdashery | Website

Nell Brown | Website

Parali by Aarushi | Website

Paula Williams | Website

Rebecca Rafferty

Sandra Tipton

SarahB | Treadled Textiles

Shelagh Brown | Website

Smita Tripathi

Studio Tuft | Website

Studio ZIA

Sue Green | Website

Susie Honnor Textiles | Website

The Little Gail Company

The Natural Fibre Company | Website

Vicky Putler | Website

Weaveaway Textiles | Website

Yamini Baars | Website

Yan Feng

-

Please note:

Pledged Green Makers have signed up to the Green Maker Initiative of their own volition and in doing so have made a commitment to reduce their environmental impact in their creative practice. However, there is no testing or validating of their claims by us. The GMI is designed to support makers on their sustainability journey, offering resources, opportunities and help. We do not offer any accreditation as of yet, and should not be used as a stamp of approval. You should always clarify with the individual or organisation any methods, materials and or techniques that they pronounce as environmentally friendly or sustainable.

Not all of our Pledged Green Makers have given their permission to be plotted on the map, so you might not find everyone from the list on the left on the map.

If you want to sign the pledge and join our Green Maker Initiative network, you can read more about it here…

GMI Awardees

GMI AWARD for MAKING IT 2025

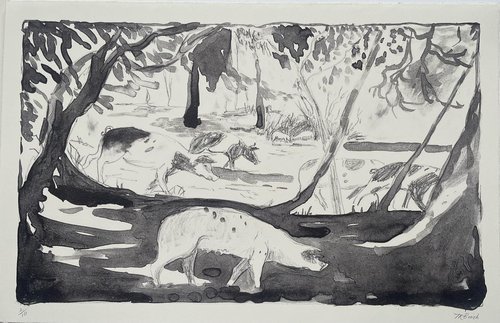

Image: display of Jamie’s work as part of the MAKING IT 2025 exhibition in MAKE Southwest’s Jubilee Gallery.

MAKING IT is MAKE Southwest’s biennial exhibition showcasing the work of emerging makers across the Southwest. Since the Green Maker Initiative launched, we have allocated a prize for makers using particularly sustainable methods, materials or techniques within their making practice.

In MAKING IT 2025, the GMI award was presented Jamie Dun (Bristol Broomworks). Jamie uses pre-industrial, heritage craft methods, hand-tying each broom with purpose. The brooms are made from natural and sustainable materials including handles made from locally sourced hazel. They are, of course, exquisitely beautiful, but they are also made to be used! Every broom in Jamie’s range has a purpose for which it was made. These are useable objects that, if cared for, can be handed down from generation to generation, far surpassing their cheap plastic counterparts.

ABOUT JAMIE

Jamie is a self-taught broom maker with a background in fashion and visual design and merchandising.

Using pre-industrial heritage craft methods, each broom is hand tied with intention a functional work of art. A connection to the land and nature. An efficient and beautiful way to clean surfaces.

Brooms are much more than a common household cleaning tool. Brooms have a history as old as humanity, across millennia, evolving with us, and are likely to be found in every dwelling on the planet. In some cultures, including our own, brooms have been a symbol for the repression of the feminine and a vehicle of damnation and misogyny.

Jamie started making brooms in her tiny kitchen in her two-bed flat in Bristol and has moved into a studio loft in a barn on a flower farm just south of Pensford in Somerset.

David Canter Memorial Fund: 2024 Awardees

GRANTS FOR CRAFT

The David Canter Memorial Fund (DCMF) offers awards to give financial assistance to those working in craft. The fund is open to those who have finished their formal training and are working full-time or part-time but need money for specific projects, e.g., setting up a workshop, buying equipment, educational work, or for research and travel. Awards made are usually up to a maximum of £500 and are made every other year, each time focusing on different craft disciplines.

Awards are available to those who have finished their formal training and are working full or part-time anywhere within the UK but need money for special projects such as setting up a workshop, buying materials and equipment, or for research and travel.

Applications to support work with community groups is not the focus of this fund. Grants are not available to students.

Awards are not usually made to cover the cost of buying consumables i.e. raw materials

In 2024, working with our Green Maker Initiative, the fund supported makers in reducing their environmental impact within their craft practice. We had 50 applicants, and many extremely strong applications. It was a tough decision, but the worthy awardees are…

Nell Swift | Textiles

Industries such as glass blowers, clay extractors and stone polishers all create some waste that cannot be recycled, and which ends up in landfill. This is often very toxic for the environment, as it is the waste sludge from the processes used, and because the particles are small, they can contaminate the ground and therefore the ground water.

Nell Swift is a weaver in natural fibres utilising custom built hand looms. She weaves garments and textiles for the home in reclaimed natural fibres-producing the least impactful fabrics in a low to zero-waste method. She is motivated by a need to de-scale production levels, produce and value quality fabrics, repair what we have and see fabrics for their technical and artistic value.

Nell was awarded the DCMF grant to fund the purchase of a drum carder to turn her limited yarn waste into new yarn. She aims to produce a tweed yarn which will echo past pieces of her work, a ghost of original projects and a yarn snapshot of her practice. The carder will allow Nell to close the loop in her practice to be zero waste from textile waste.

Nell has already gone to great lengths to reduce the environmental impact of her creative practice - her looms are restored or custom built, her studio is highly insulated, passive solar and built from construction waste using removeable foundations. Rainwater is harvested for wet finishing and solar PV provides additional lighting and dobby control.

Imogen Taylor-Noble | Ceramics

Imogen Taylor-Noble is a researcher, maker, kiln builder, teacher, questioner, activist, re-wilder: using what she has to make what she can, within the broader scope of a socially engaged ceramics practice.

Imogen’s focus for a long time has been investigating how it is possible to be not only a green maker, but to explore regenerative approaches to making ceramic objects, as well as how to be a carbon neutral ceramicist. Her ceramics practice also encompasses teaching, where she shares ideas about responsible making, glazing and studio management with her students.

Imogen was awarded the DCMF grant to fund the scoping phase of a project to investigate the possibility of making 100% industrial waste stream glazes to use in her practice.

Imogen will work with local companies to use their waste sludge to research, make and test glazes on her own work and offer to her students in place of readily available ones on the market. Testing the model and recipes so that they could be made available commercially on a small scale.

Using these sludges in place of regular glaze ingredients can divert these pollutants and can also prevent the environmental cost of the extraction for them in the first place.

Beca Beeby | Metal

Beca Beeby is a blacksmith and sculptor turned small-scale: her organically formed jewellery and sculpture are inspired by microscopic and macro exploration of the natural world. Having worked with 'industrial' metals such as cast iron and steel, Beca has recently downscaled her work to enable a faster, more playful development of ideas and to work in a way that is less wasteful and less damaging to the environment.

Beca draws on her previous experience in casting but scaled down and developed to utilise the lost wax casting method to suit her needs. Though Beca carves her pieces onsite she must send her work off to a casting foundry to be cast.

Beca notes that at each step the environmental impact of what she does is considered, from recycled materials and packaging to non-toxic acids and a solar powered workshop. She avoids polishing compounds due to their environmental impact, instead using a pin polisher as needed.

Beca was awarded the DCMF grant to fund the purchase of a kiln, the final piece of the puzzle to enable her to cast her own work using the lost was casting method. Beca will cast using beeswax instead of the polymer waxes usually used and, unlike the casting foundry, she will be reclaiming the wax in order to use it time and time again.

Casting her own pieces will mean no unnecessary transportation of goods, reducing carbon emissions, and the kiln we be incorporated into her solar powered workshop

Josephine Birch | Printmaking

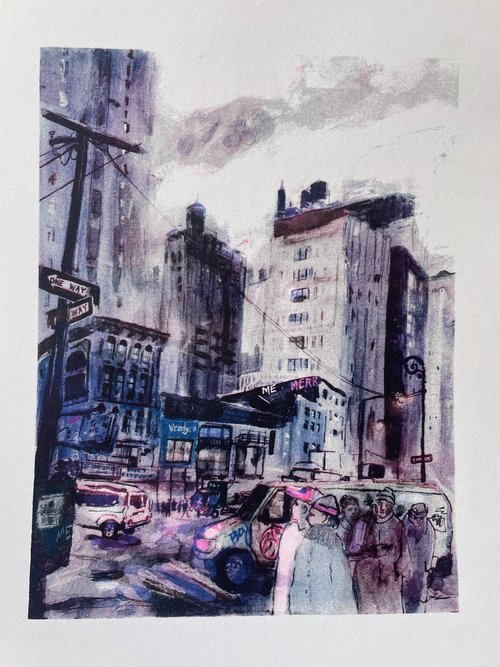

Josephine Birch is an illustrator and printmaker specialising in monoprint and lithography. On the strength of her drawing, Josephine has been the recipient of multiple awards, exhibited worldwide, awarded multiple residencies and is a published illustrator. She is currently self-building her print room in an industrial farm unit in South Devon with a view to teaching and editioning.

Lithography is categorised by the Heritage Crafts Association as an endangered craft, meaning the discipline has sufficient craftspeople to transmit the craft skills to the next generation, but there are serious concerns about its ongoing viability.

Lithography is a costly process that requires specialist equipment, likely contributing to its decline. Much like other lithographers, Josepine’s work starts on location through drawing and painting but then she has to travel to Bristol, the closest lithography provision, to be able to print!

Josephine was awarded the DCMF grant to fund the purchase of two vital pieces of studio equipment: a gum blanket for a recently purchased off-set litho press, and a large spindle roller required for inking lithographic plates.

This purchase would enable Josephine’s studio to become a specialist workshop space for lithography in Devon, creating more rural arts opportunities for the local community and a specialist resource for devon-based printmakers. Josephine will also be able to teach this specialist subject, increasing an endangered craft’s viability and keeping the process alive.

Printing and teaching in house will not only drastically reduce Josephine’s carbon emissions but will also cut the carbon emissions of other printmakers who may have had to travel to Bristol to use this specialist recourse too.

About the David Canter Memorial Fund

The establishment of the fund in 1988 was made possible by generous support from David Canter’s friends and colleagues, wishing to show their appreciation of his great contribution to the Crafts, following the initial proposal and funding from the Craft Potters Association 1984. The fund also acknowledges with thanks the help and support of MAKE Southwest.

David Canter’s love and enthusiasm for the Arts and Crafts was a deep inspiration to all who knew him. His vision of the highest aesthetic standards uncompromised by commercial considerations was expressed in his creation of Cranks restaurants, which he founded and designed, and Craftwork shops in which he brought together an unrivalled collection of crafts from all over Britain.

David was Honorary Secretary of the Craft Potters Association for over 20 years, and during this time he pioneered the setting up of the Association’s first retail outlet in London. In his work as Chairman of the Crafts Council Grants Committee, and co-founder of the Dartington Pottery Training Workshop, he showed his commitment to helping and advising young craftspersons.